Chiller for Tape Plant

100000.0 आईएनआर/टुकड़ा

उत्पाद विवरण:

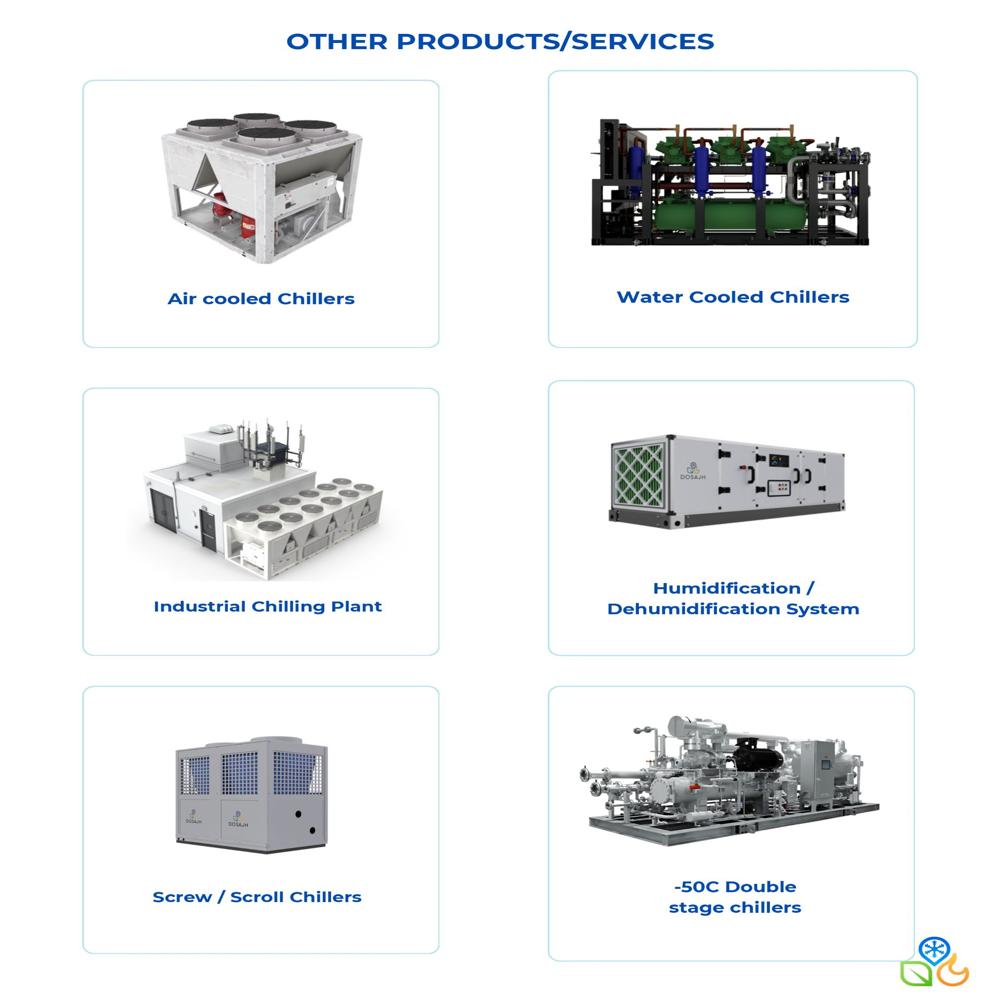

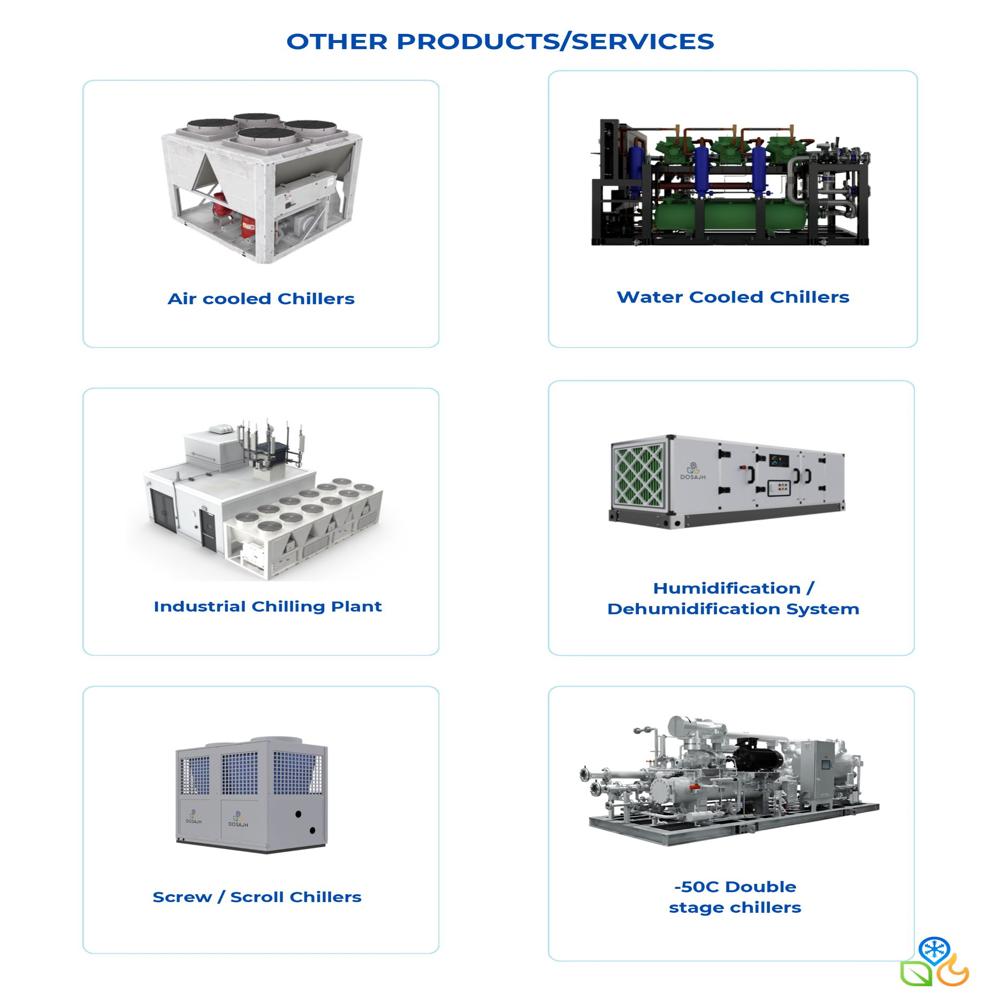

- प्रॉडक्ट टाइप Air Cooled Chiller

- उपयोग Industrial

- साइज Standard

- शर्त

- मटेरियल MS

- वोल्टेज वोल्ट (v)

- म्यूट करें 1

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Air Cooled Chiller

- Industrial

- MS

- 1

- 1 Year

- Standard

- वोल्ट (v)

व्यापार सूचना

- प्रति महीने

- हफ़्ता

- No

उत्पाद वर्णन

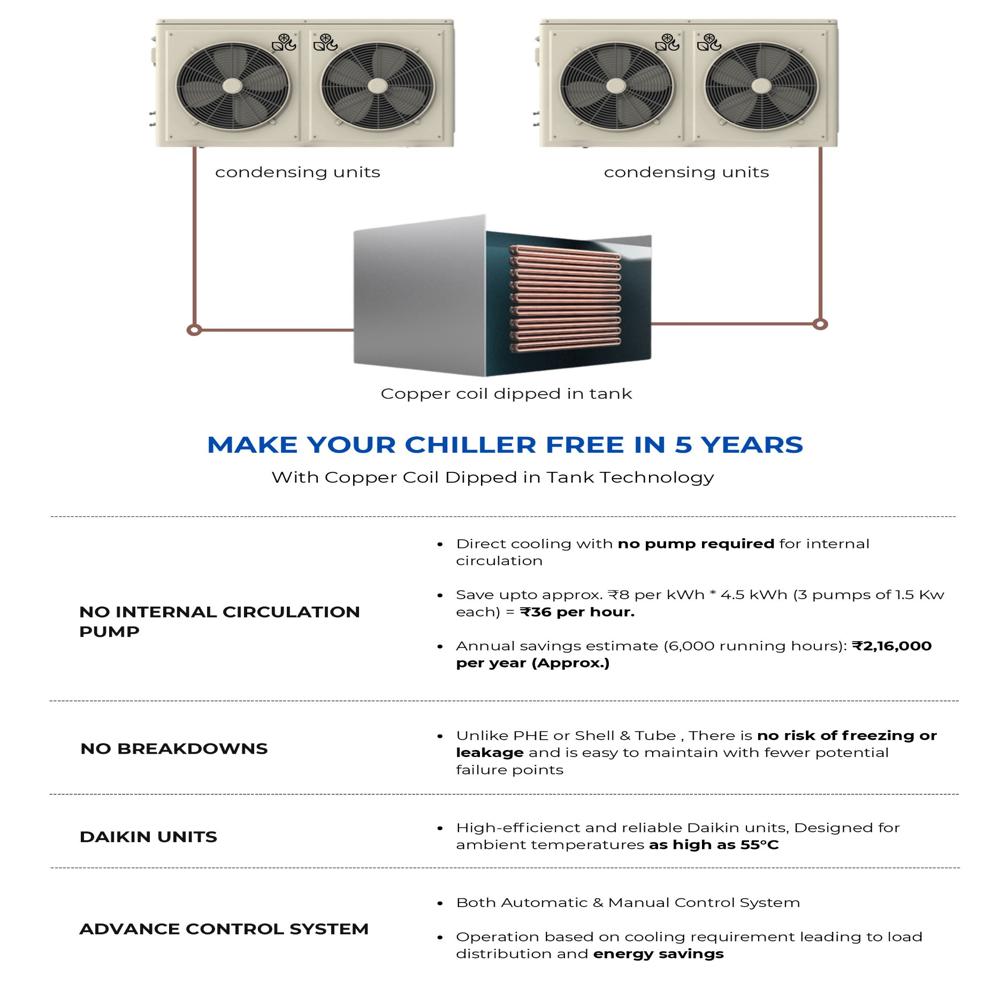

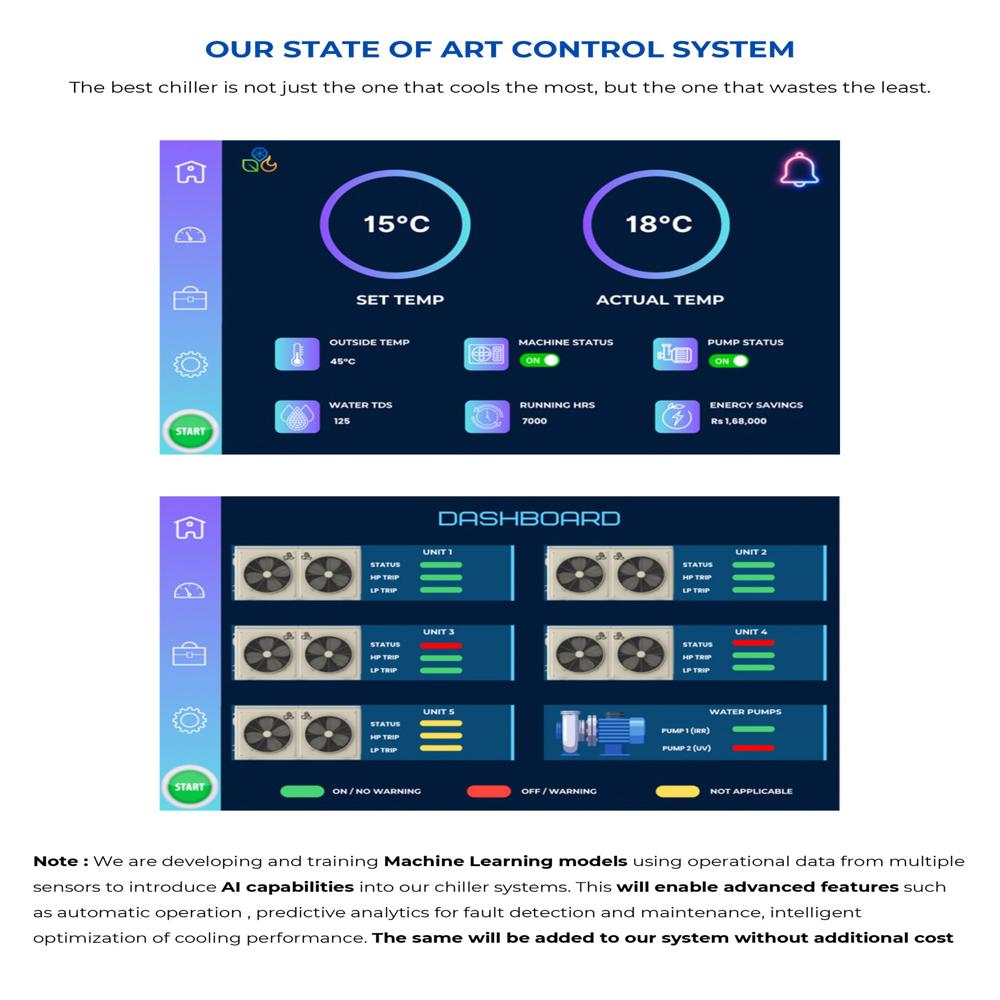

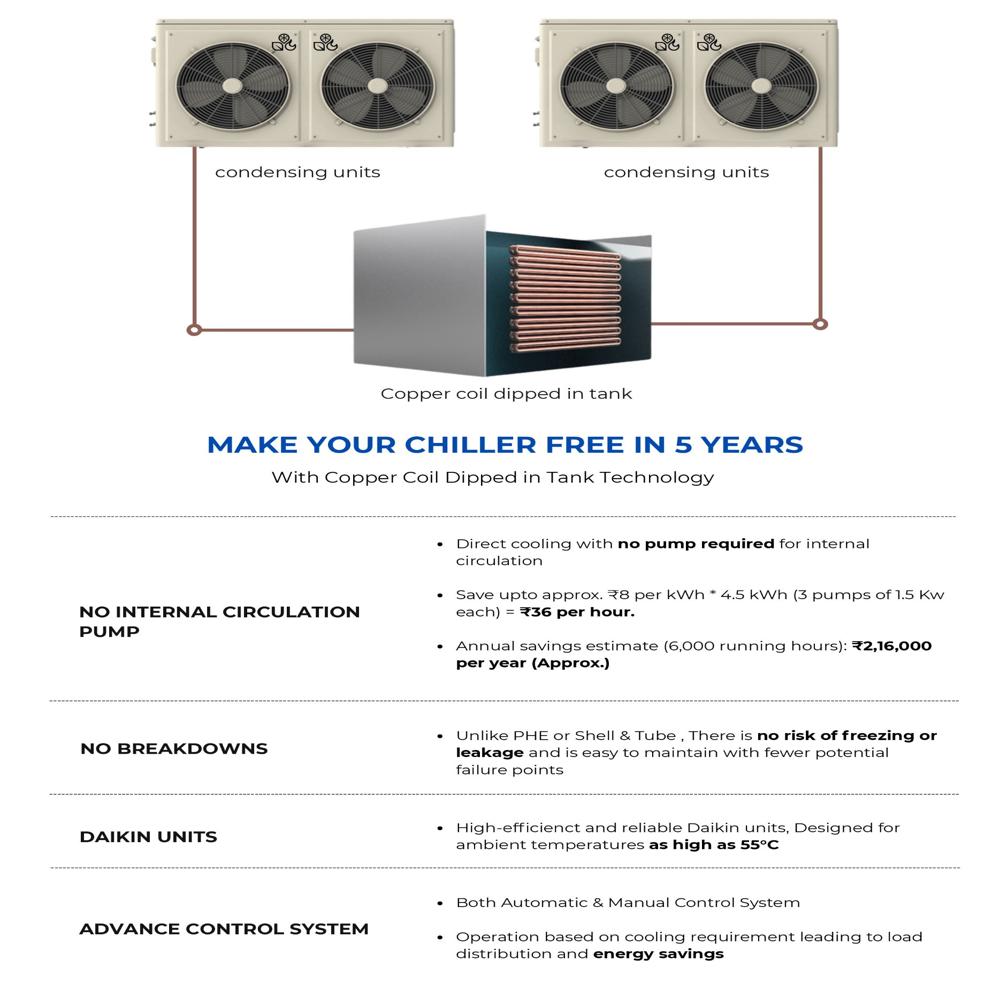

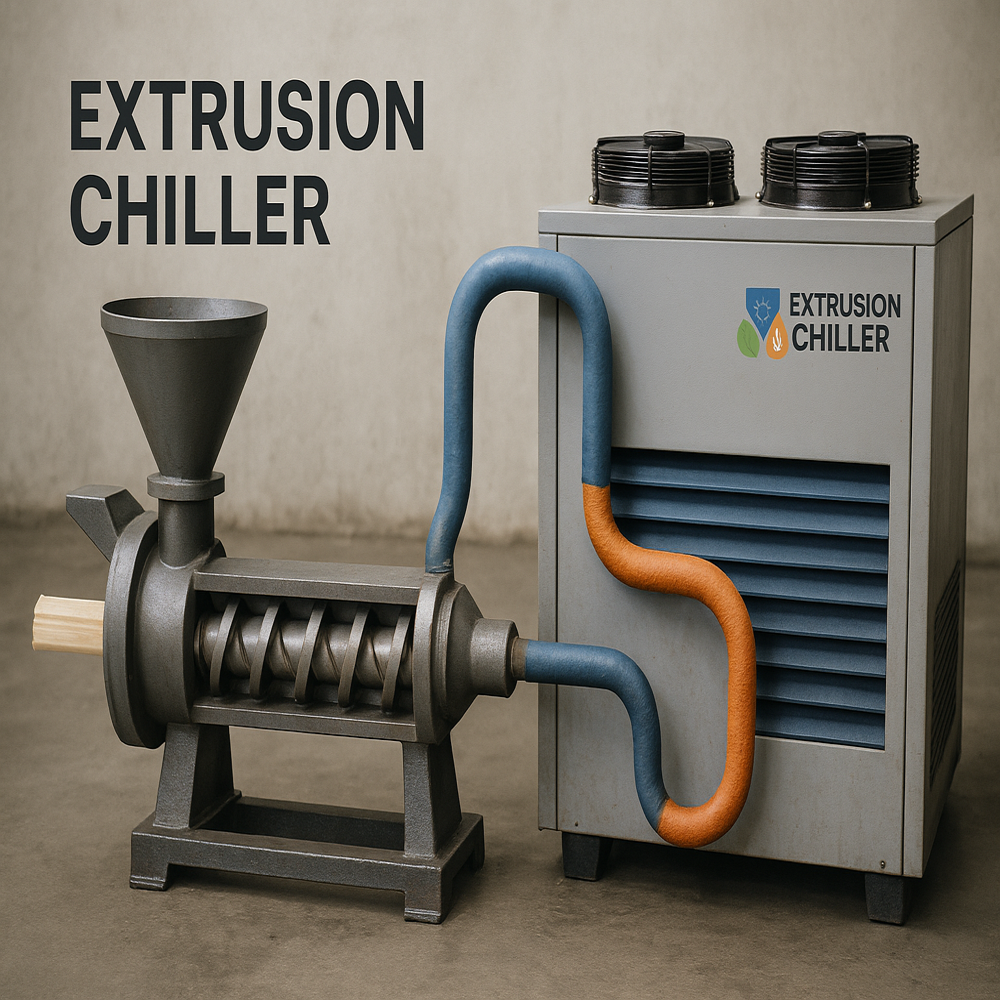

Ensure smooth, high-speed production with ourIndustrial Chiller for Tape Plant, specially designed for BOPP, PP, and polyester tape manufacturing lines. This precision cooling system helps maintain optimal extrusion temperature, enhances film clarity, and increases machine lifespan.Key Features: Accurate Temperature ControlProvides uniform cooling to die heads, rollers, and water tanks for superior tape quality. Energy-Efficient DesignIncorporates advanced compressors and eco-friendly refrigerants to reduce power consumption. Rugged & ReliableBuilt with heavy-duty components to withstand round-the-clock operation in industrial environments. Easy to Operate & MaintainUser-friendly control panel, auto cut-off system, and low-maintenance design. Available in Multiple CapacitiesRanges from 3 TR to 50 TR to suit different tape plant sizes and output requirements. Applications: BOPP Tape Plant PP & Polyester Tape Lines Adhesive Tape Manufacturing Mono Filament and Extrusion Plants Why Choose Our Tape Plant Chiller? Improves Tape Surface Finish & Strength Prevents Machine Overheating Enhances Production Speed & Product Consistency Compatible with All Major Tape Plant BrandsTechnical Specifications (Sample): Cooling Capacity: 3 TR 50 TR Temperature Range: 5C to 25C Power Source: 3 Phase, 50/60 Hz Refrigerants: R-407C / R-134A (eco-safe)FAQs of Chiller for Tape Plant:

Q: What is the voltage compatibility of the Chiller for Tape Plant?

A: The Chiller for Tape Plant operates at a voltage range of 220-415 Volt (v).Q: What is the material used for the construction of the Chiller for Tape Plant?

A: The Chiller for Tape Plant is constructed using MS (Mild Steel).Q: Is the Chiller for Tape Plant suitable for industrial usage?

A: Yes, the Chiller for Tape Plant is designed specifically for industrial usage.Q: Does the Chiller for Tape Plant come with a warranty?

A: Yes, this product comes with a warranty of 1 Year.Q: What is the condition of the Chiller for Tape Plant?

A: The Chiller for Tape Plant is available in new condition.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें